Tower System

Ideal for heavy-load stage and lighting setups

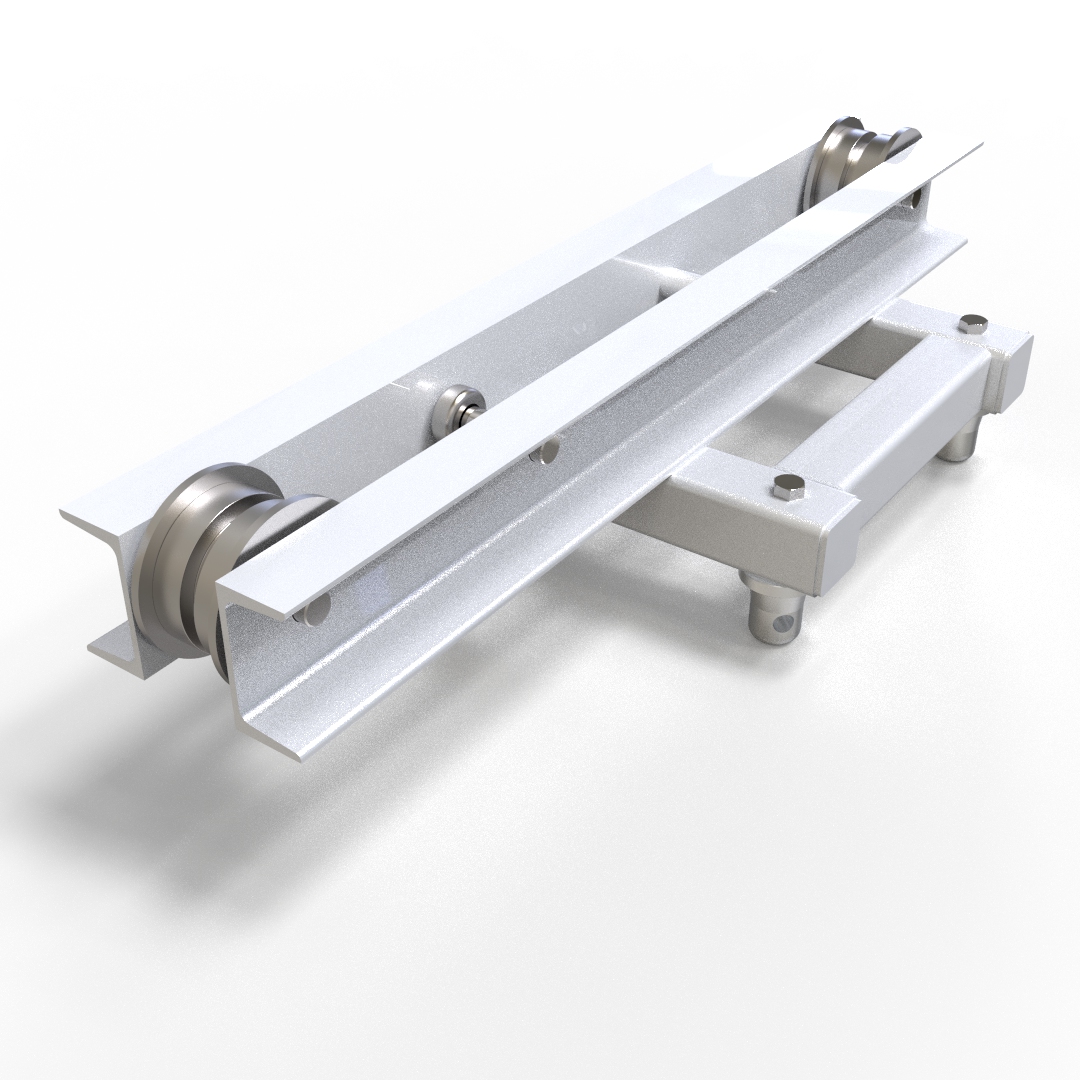

Top Plate – ST-38-LD:

Model Codes: ST-38-LD

Description: The Top Plate of ST-38-LD is a precision engineered load-bearing assembly designed for use with the ST-38-LD truss tower system. Fabricated from high strength mild steel and alloy components, this top plate provides stable and secure mounting for hoisting, rigging, or structural extensions. It features dual RHS sections, an integrated pulley system suitable for both motorized hoists and manual chain blocks, high-grade bearings, and half-male connectors—offering both mechanical durability and functional versatility for medium-duty lifting applications.

Key Specifications:

Material:

Top & Bottom Tubes: Mild Steel YST 310 80×40×3.0mm

Pulley & Rods: 42CrMo4 Alloy Steel (Grade 1.7225)

Top Plate Length: 930mm

Bottom Plate Length: 385mm

Bore Bush: Ø25×2.0mm

Connectors: 50mm Half Male (x4)

Pulley Load Rating: 2 Ton

Pulley Bearings: SKF 62_22_2_01 (x8)

Pulley Rod Diameter: 22mm

Bolt Specification: IS 3640 – M14×105mm HT Bolts

Features:

Robust mild steel and alloy construction

Compatible with 2-ton hoist systems

Integrated dual-pulley assembly

Suitable for motorized hoists and manual chain blocks

SKF bearings for smooth operation

Standardized chamfering and bolt interface

Q/C approved and FPA compliant design

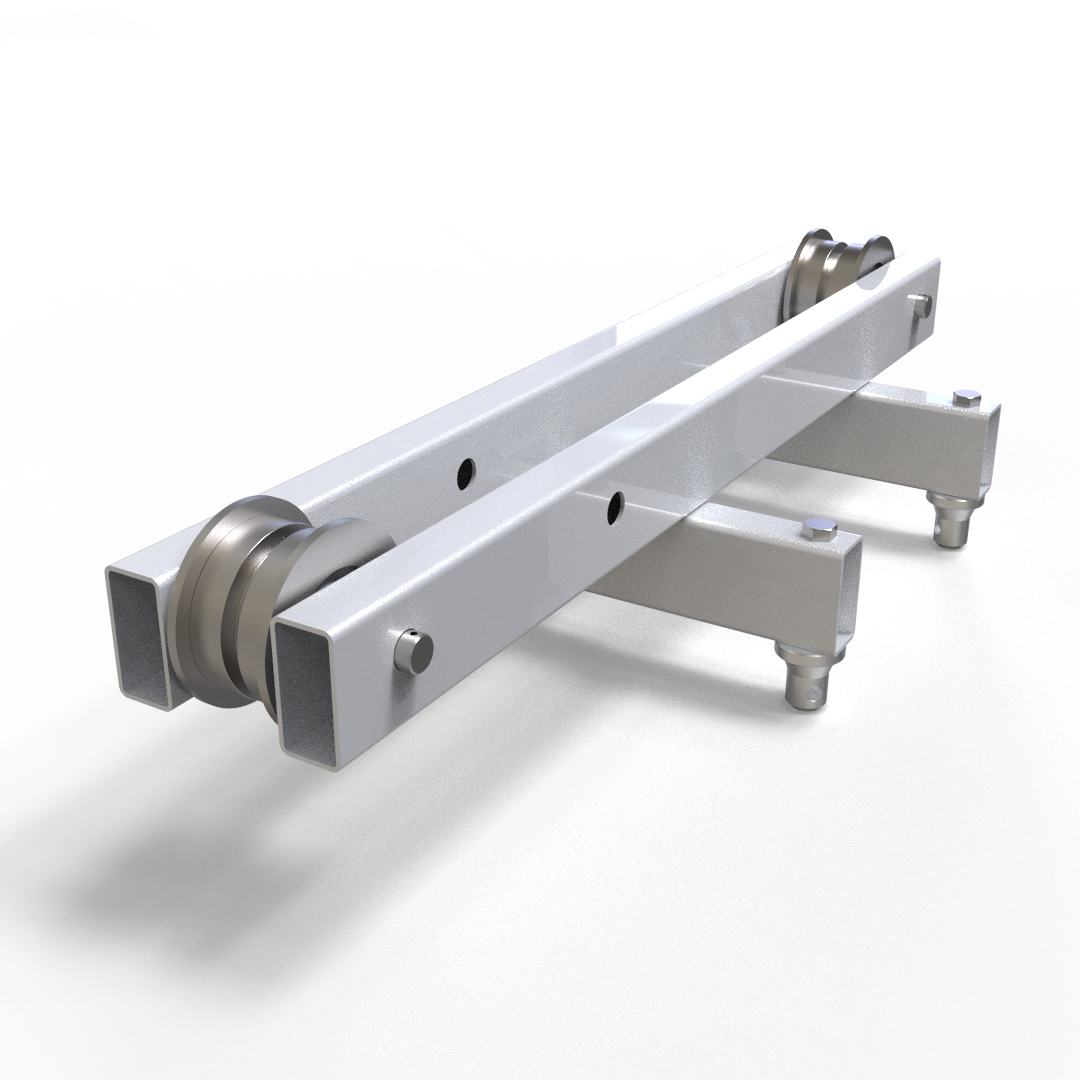

Top Plate – ST-38-HD/XHD:

Model Codes: ST-38-HD-XHD

Description: The Top Plate of ST-38-HD/XHD is a heavy-duty steel structure engineered to support lifting systems in high-load tower truss setups. This assembly is designed with robust channel sections, dual square hollow tubes, and integrated pulley systems, making it ideal for demanding event environments. It comes complete with SKF bearings, high-tensile bolts, and a 4.75-ton D-shackle for secure rigging and load-bearing performance.

Key Specifications:

Top Channel: C-Channel 100×50×5mm – Mild Steel (x2, 930mm each)

Bottom Tubes:

Tube-01: SHS 60×60×4.0mm (x2, 405mm)

Tube-02: SHS 50×50×3.0mm (x2, 285mm)

Support Tube: Ø25×2.0mm (Mild Steel)

Top Pulley Rods: Ø22mm × 105mm – 42CrMo4 (x3)

Top Pulleys: 2-Ton Capacity – 42CrMo4 (x2)

Bearings: SKF 62_22_2_01 (x8)

Shackle: 4.75 Ton D-Shackle (Alloy Steel)

Connectors: 50mm Half Male – 42CrMo4 (x4)

Bolts: M14 × 80mm HT Hex Bolts (x4) – Alloy Steel

Features:

Heavy-duty structure for extra load-bearing truss towers

Triple pulley rod setup for enhanced lifting precision

D-Shackle included for safe rigging

Smooth pulley rotation using SKF bearings

Designed with production safety and FPA (First Part Approval)

compliance

Q/C certified parts only

Base – ST-38 (305 / 385 Series):

Model Codes: BS-ST-38-H

Description: The Base Plate Assembly for ST-38 truss towers is a robust, fully-integrated foundation system designed for both 305mm and 385mm tower configurations. Engineered from precision-formed mild steel, it includes a modular combination of connectors, wheel systems, and outriggers for safe, adjustable, and mobile support. This assembly ensures reliable load distribution and easy mobility, even under heavy-duty operational environments.

Key Specifications:

Compatible Truss Series: ST-38 (305mm / 385mm)

Main Frame Dimensions: 2960mm (L) × 335mm (W)

Material: High-grade Mild Steel

Height Adjustability: DR-M22 height adjustors (x8)

Mobility:

Wheel Assemblies (x4) – Bolt-on or weldable

Outriggers for stabilization (x4) – DR-OT-38-H

Locking Pins – DR-OT-PIN-38-H (x4)

Connector Type: 50mm Half Male (x4)

Bolts for Connectors: M14 × 120mm – IS 3640 Standard

Main Tubes: 96×48×3.0mm (Lengths: 1150mm and 551mm)

Outer Tubes: 80×40×3.0mm (722.1mm)

Outrigger Tubes: 80×40×3.0mm (1100mm)

Stabilizer Flats: 50×10mm

Upper Flat for Pins: 40×5mm

End Cap: 3–5mm per tube dimension

Tube Specifications:

Main Tubes: 96×48×3.0mm (Lengths: 1150mm and 551mm)

Outer Tubes: 80×40×3.0mm (722.1mm)

Outrigger Tubes: 80×40×3.0mm (1100mm)

Stabilizer Flats: 50×10mm

Upper Flat for Pins: 40×5mm

End Cap: 3–5mm per tube dimension

Hybrid Base – SST-38 (HD/XHD):

Model Codes: BS-ST-38-HD-XHD

Description: The Hybrid Base for SST-385 HD/XHD series is a heavy-duty, mobility-enabled support base designed for large scale tower truss structures. Built using premium YST-310/355 grade steel, this base assembly ensures strength, adjustability, and ease of movement in event or industrial setups. With high bid weld-reinforced plates and precision-fit components, it is engineered to deliver superior load support and stability in all directions.

Key Specifications:

Base Dimensions: 898mm × 335mm

Frame Material: YST-310 High-Strength Steel

Plates: 8mm Thick – YST-355 Grade

Design: Welded reinforced top & bottom frame

Height Adjustability: M-28 Height Adjustors (x4) – EN-19

Mobility:

Heavy-duty Caster Wheels (x4)

Wheel-attachable via bolt or weld

Connector System:

50mm Half Male Connectors (x4) – EN-19

Fastened with M14 × 120mm

High-Tensile Hex Bolts (x4) – Alloy Steel

Tube Sections:

Main Tubes (96×48×3.0mm) in multiple

lengths: 734.1mm, 519.1mm, 1086.2mm

Adjustor Tube: Ø37.7×2.0mm

SLEEVE BLOCK ST-65-SB-HD/XHD:

Model Codes: ST-65-SB-HD-XHD

Description: The ST-65-SB-HD-XHD Sleeve Block is an essential structural component for the ST-65 HD and XHD truss series, designed to enable vertical lifting and secure positioning of heavy-duty truss spans. This precision engineered assembly allows safe integration with hoist systems and M20 eye bolts, ensuring high-load handling and operational safety in event and industrial rigging setups.

Key Specifications:

System Compatibility: ST-65-HD & ST-65-XHD Truss Series

Tube Size: 60×60×4.0 mm

Assembly Weight: Approx. 81,226.2 g

Eye Bolt Mounting: M20 compatible

Tyre Size: Ø67 mm nylon wheels

Materials:

Tubes & Plates: YST-310 / YST-355

Connectors: EN-19 alloy

Tyres: Nylon

Bolts: Alloy Steel (M10 & M14)

Assembly Components:

Top, Middle, and Bottom Main Tubes

Vertical & Mid Tubes

16 Braces (Ø25×3.0 mm)

32 Tyre Plates & 16 Nylon Tyres

2 Shackle Plates for secure coupling

16 Half Male Connectors with bolts

Key Features:

Heavy-duty construction with reinforced tubing

Integrated tyre system for smooth truss movement

Chamfered edges and ISO:2768 tolerance compliant

Designed for safe load distribution and vertical rigging

SLEEVE BLOCK ST-77-SB-HD:

Model Codes: ST-77-SB-HD

Description: The ST-77-SB-HD Sleeve Block is a robust structural component tailored for the ST-77 HD truss series. Designed to ensure safe vertical lifting, alignment, and smooth travel along truss towers, it integrates seamlessly with M20 eye bolt hoists. Its reinforced square tube frame and nylon tyre assembly ensure high load capacity and mobility under rigging stress.

Key Specifications:

System Compatibility: ST-77-HD Truss Series

Tube Dimensions:

Main Tubes: 60×60×4.0 mm

Mid Tube: 50×50×3.0 mm

Vertical Tubes: 60×60×4.0 mm

Eye Bolt Compatibility: M20

Weight (Approx.): 81,226.2 g

Material:

Frame: YST-310

Plates: YST-355

Connectors: EN-19

Wheels: Nylon

Bolts: Alloy Steel

Component Breakdown:

4 Top and 4 Bottom Main Tubes

4 Vertical Tubes, 4 Mid Tubes

16 Braces (Ø25×3.0 mm)

32 Tyre Plates with 16 Nylon Tyres

16 Half Male Connectors with M14 bolts

2 Shackle Plates for hoist linkages

Key Features:

Designed for high-strength vertical load handling

Fitted with nylon wheels for guided movement

Corrosion-resistant, durable construction

Precision tolerances conforming to ISO:2768

Chamfered edges for safety and clean assembly

Base Plate – ST-40-HD :

Model Codes: BS-ST-40-HD

Description: The ST-40-HD Base Plate Assembly is a heavy duty, ground-level support system tailored for the ST-40-HD truss series. Constructed from precision-formed mild steel and equipped with mobility and leveling options, this assembly provides rock-solid stability and field adaptability for large-scale rigging structures. With bolt-on or weldable wheels, eight-point height adjustability, and integrated

outriggers, it ensures maximum load distribution and structural integrity.

Key Specifications:

Frame Size: 3120mm × 355mm

Compatible Truss Size: 405mm × 405mm (ST-40 Series)

Material: High-grade Mild Steel

Main Tubes:

122×61×4.5mm

Outer Tubes: 96×48×3.0mm

Connectors: 50mm Half Male (x4) – Bolt-on

Fasteners: M14 × 145mm HT Hex Bolts (x4)

Mobility Option:

Heavy-duty Wheels (x4) – Bolt or weld option

Height Adjustability: DR_M28 Height Adjustors (x8)

Outriggers:

DR-OT-40-H – 1180mm Stabilizer Tubes (x4)

DR-OT-PIN-40-H Locking Pins (x4)

Finish: Chamfered edges (0.5×45°), burr-free

Compliance: ISO:2768 tolerance, Q/C certified, FPA-ready

Features:

Rigid base for tower truss installations

Flexible mobility (removable wheels)

Enhanced leveling via 8 adjustable height points

Wide tube base design ensures balance and load spread

Modular and compatible with ST-40 truss series

Hybrid Base Plate – ST-40:

Model Codes: BS-ST-40-Hybrid

Description: The BS-ST-40-Hybrid is a multi-functional hybrid base plate designed for the ST-40 truss series. With a robust steel frame, integrated mobility, and triple-point ground adjustment, this unit delivers superior flexibility for both indoor and outdoor stage environments. Its extended frame structure allows it to be positioned at corners or center points in concert stages or exhibition booths, while adjustable components ensure stable performance across uneven surfaces.

Key Specifications:

Frame Size: 3120mm × 355mm

Compatible Truss: 405mm × 405mm (ST-40 Series)

Material: High-grade Mild Steel

Main Tubes: 122 × 61 × 4.5 mm

Outer Tubes: 96 × 48 × 3.0 mm

Support Plate Thickness: 8 mm

Connectors: 50mm Half Male (x4) – Bolt-on and Welded

Finish: Chamfered edges (0.5 × 45°), burr-free

Tolerance Standard: ISO:2768

Compliance: FPA-ready and Q/C approved

Mobility & Adjustment:

Heavy-duty Caster Wheels: 4 units (Bolt or Weld attachment)

Height Adjustors: DR-M28 threaded base adjustors (x8)

Outriggers:

Stabilizer Tubes – DR-OT-40-H (x4)

Locking Pins – DR-OT-PIN-40-H (x4)

Features:

Compatible for both straight and corner truss support

Designed for indoor shows, outdoor concerts, and exhibitions

Three-point adjustable leveling system ensures precise alignment

Supports both mobile and fixed configurations

Engineered for heavy loads with enhanced footprint stability

Fast assembly and easy transport

Top Plate – ST-40-LD:

Model Codes: TP-ST-40-LD

Description: The Top Plate for the ST-40-LD truss system is a light-duty lifting interface, precisely engineered to handle high-load structural requirements. Designed with a 405mm × 405mm footprint and integrated 2-ton pulley support, this component ensures seamless load transfer from hoisting systems into truss towers. Built from reinforced mild steel and high-tensile alloy components, it

ensures long-lasting durability in demanding rigging environments.

Key Specifications:

Outer Dimensions: 405mm × 405mm

Top Tube: RHS 96×48×3.0mm – Length: 910mm (x2)

Bottom Tube: RHS 96×48×3.0mm – Length: 385mm (x2)

Material: Mild Steel (Frame) + Alloy Steel (Connectors & Pulleys)

Bolt Bush: Ø25 × 2.0mm – Length: 90mm (x4)

Connectors: 50mm Half Male – 42CrMo4 (x4)

Pulley: 2-Ton Capacity with SKF Bearings (x2)

Pulley Rod: Ø22mm × 200mm – 42CrMo4 (x2)

Fasteners: M14 × 105mm HT Hex Bolts – IS 3640 standard (x4)

Features:

High-load bearing capacity suitable for truss hoist applications

Integrated pulley system with SKF bearings for smooth operation

Durable high-strength steel structure with precision chamfering

Modular bolt-on half-male connector design

ISO:2768 manufacturing tolerance and FPA-compliant production

Applications:

Top connection for ST-40-HD vertical truss towers

Manual or motorized hoist integration

Structural transition point in load-bearing truss systems

Event and industrial rigging for lighting, sound, or displays

Top Plate – ST-40-HD:

Model Codes: TP-ST-40-HD

Description: The Top Plate for ST-40-HD is a structurally reinforced steel assembly designed to support lifting and hoisting mechanisms atop heavy-duty truss towers. It integrates dual C-channels, welded box tubing, and precision-aligned pulley systems to deliver reliable support for both manual and motorized hoist applications. Engineered for 2-ton load handling, the unit is fabricated from mild steel and high-grade alloy components to meet rigorous industry performance standards.

Key Specifications:

Top Channels: C-Channel 100×50×5.0mm – Length: 910mm (x2)

Bottom Tubes:

SHS 60×60×4.0mm – Length: 425mm (x2)

SHS 50×50×3.0mm – Length: 295mm (x2)

Support Tube: Ø25×2.0mm – Length: 75mm

Pulley Rods: Ø22mm × 105mm – Material: 42CrMo4 (x2)

Pulleys: 2-Ton Load Capacity – Material: 42CrMo4 (x2)

Bearings: SKF 62_22_2_01 (x8)

Connectors: 50mm Half Male – Length: 53mm – Material: 42CrMo4 (x4)

Fasteners: M14×80mm HT Bolts (IS 3640 Standard) – Alloy Steel (x4)

Material Composition: Mild Steel + Alloy Steel

Surface Finish: Chamfered (0.5×45°), Deburred

Tolerances: As per ISO:2768

Features:

Designed for ST-40-HD truss towers (405mm series)

Dual-pulley setup for hoist and chain block lifting

High-strength construction for load-intensive setups

Fully welded frame with cross-structural stability

Compatible with standard spigot truss systems

Q/C approved and FPA-compliant

Applications:

Top lifting interface for truss towers

Event rigging and roof hoist support AV and lighting structures

Load transition point for motorized winch systems

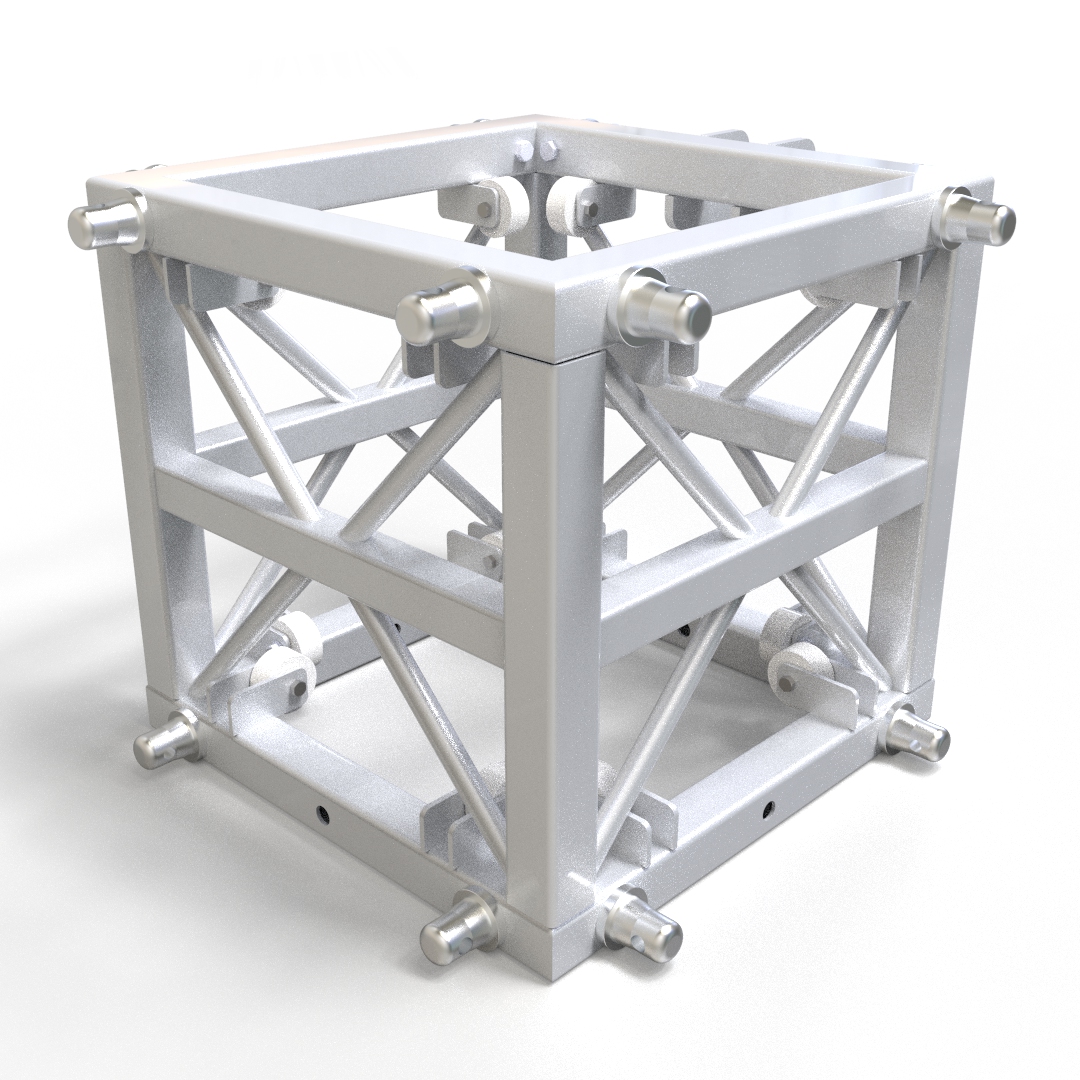

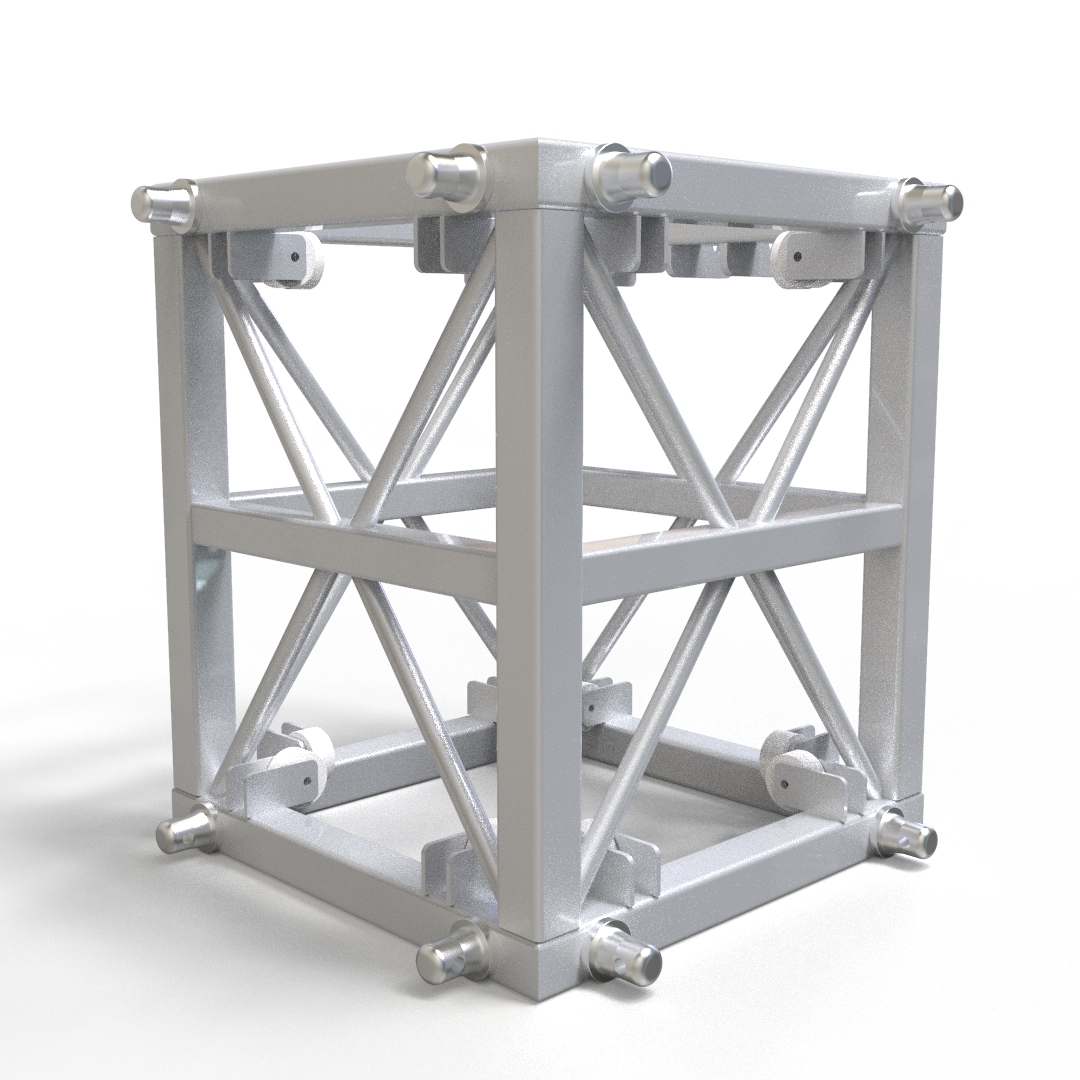

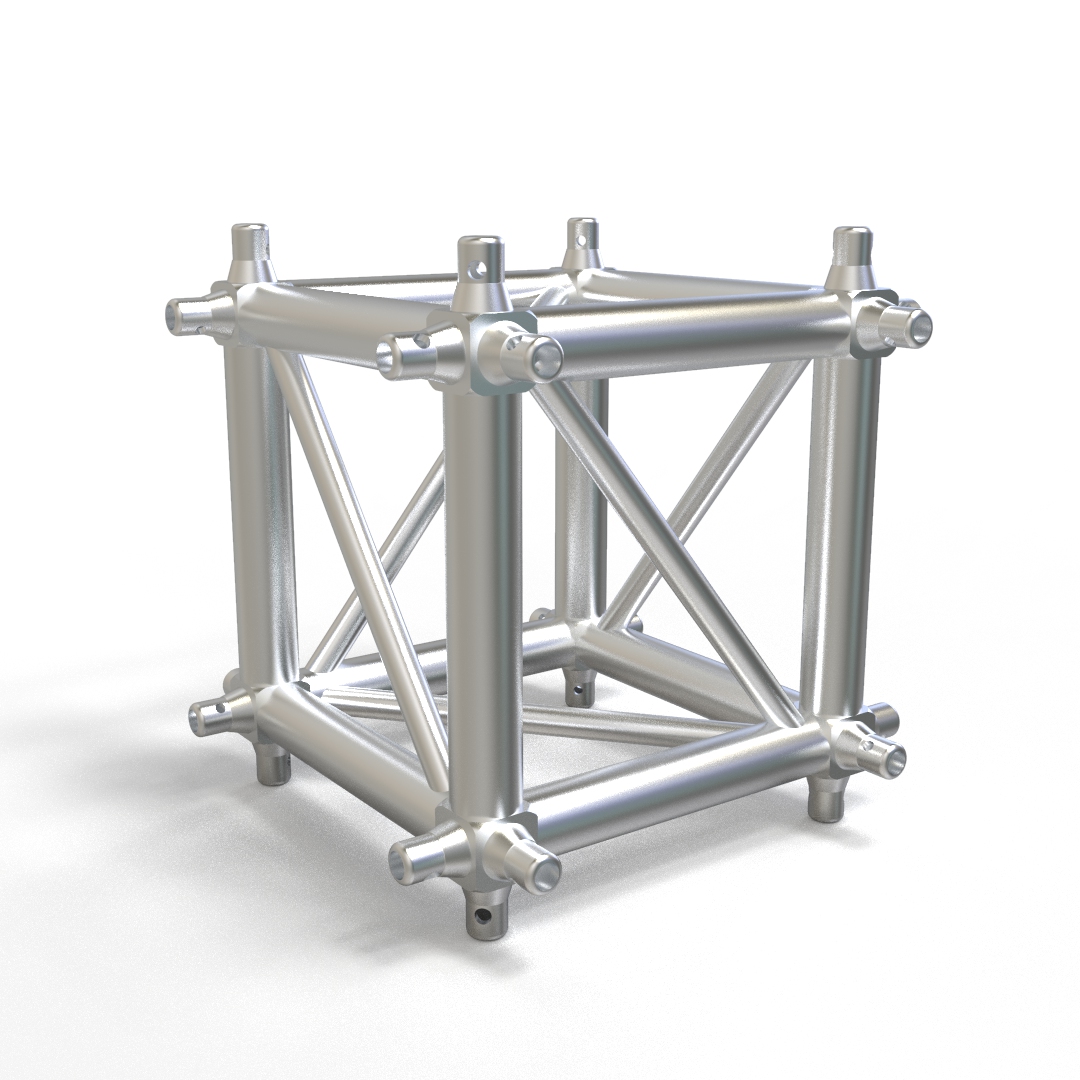

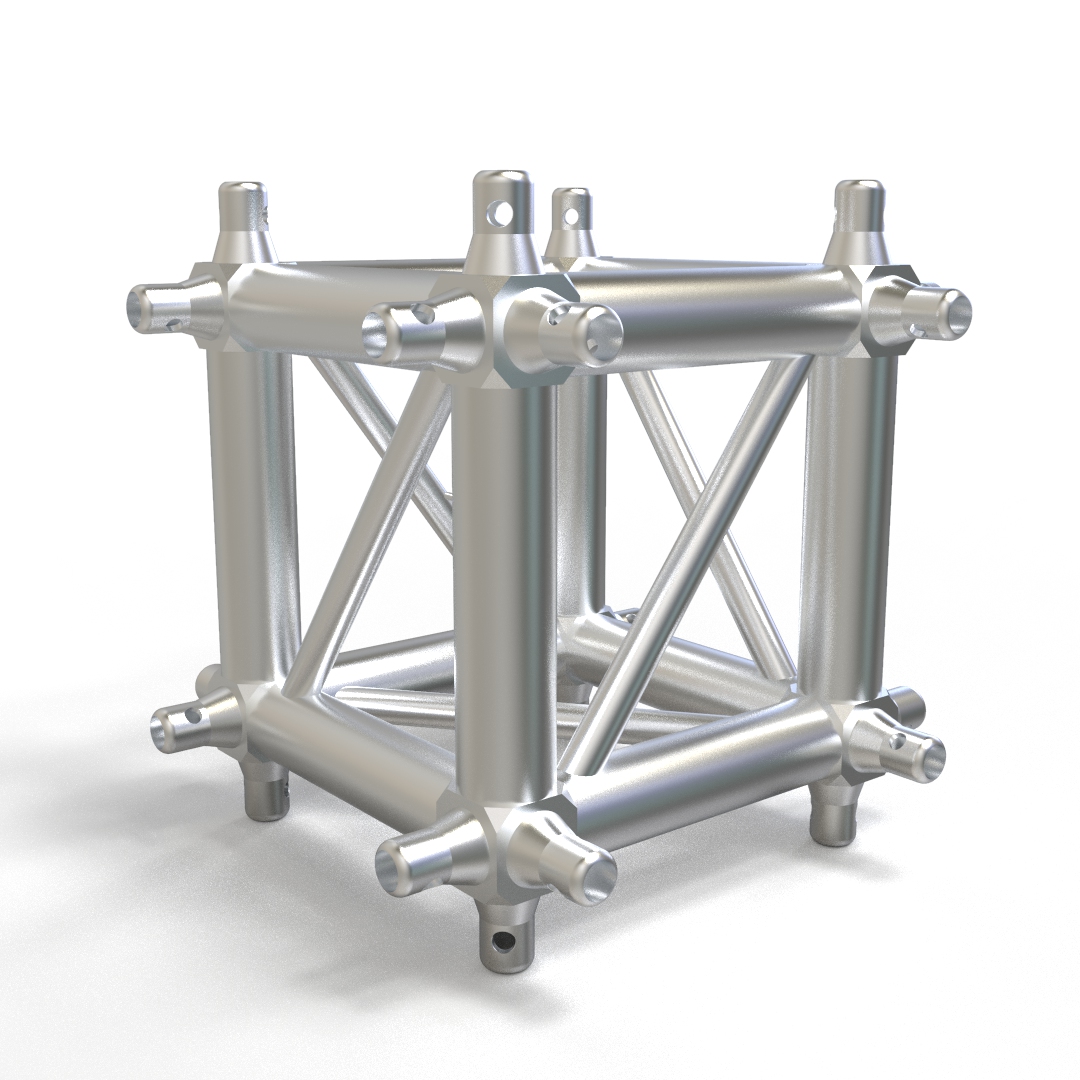

Aluminium Corner Block – Series:

Available Model : CB-305, CB-385, CB-405, (Customization Also Available)

Description: The Aluminium Corner Block – 385 Series is a high-strength modular truss junction designed for 50mm tube systems, offering exceptional stability and load-handling performance in multi-directional configurations. With a cube form factor and 50×50×50mm corner blocks, this unit ensures secure and seamless connectivity across truss lines. Its enhanced main and brace profiles are engineered for medium- to heavy-duty event, exhibition, and installation requirements.

Key Specifications:

Corner Block Size: 385mm x 385mm

Main Chords: Ø50×3.0mm

Braces: Ø25×3.0mm

Corner Nodes: 50×50×50mm

Connectors: Ø50×45.0mm Half Male Hollow

Material: Aerospace-grade Aluminium Alloy

Finish: Brushed or polished finish with deburred edges

Connection Type: Spigot-compatible with hollow pin system

Weld Type: TIG-welded joints for maximum strength

Features:

Designed for 50mm modular truss systems

Heavy-duty aluminium construction with sleek finish

Precision welding and fitment for seamless connectivity

Corner block design improves structural efficiency

Lightweight yet engineered for durability in load-bearing setups

Applications:

Large-format truss systems and stage corners

Exhibition and event framework junctions

Suspended grid support or overhead truss transitions

Fixed architectural lighting or display mounting structures